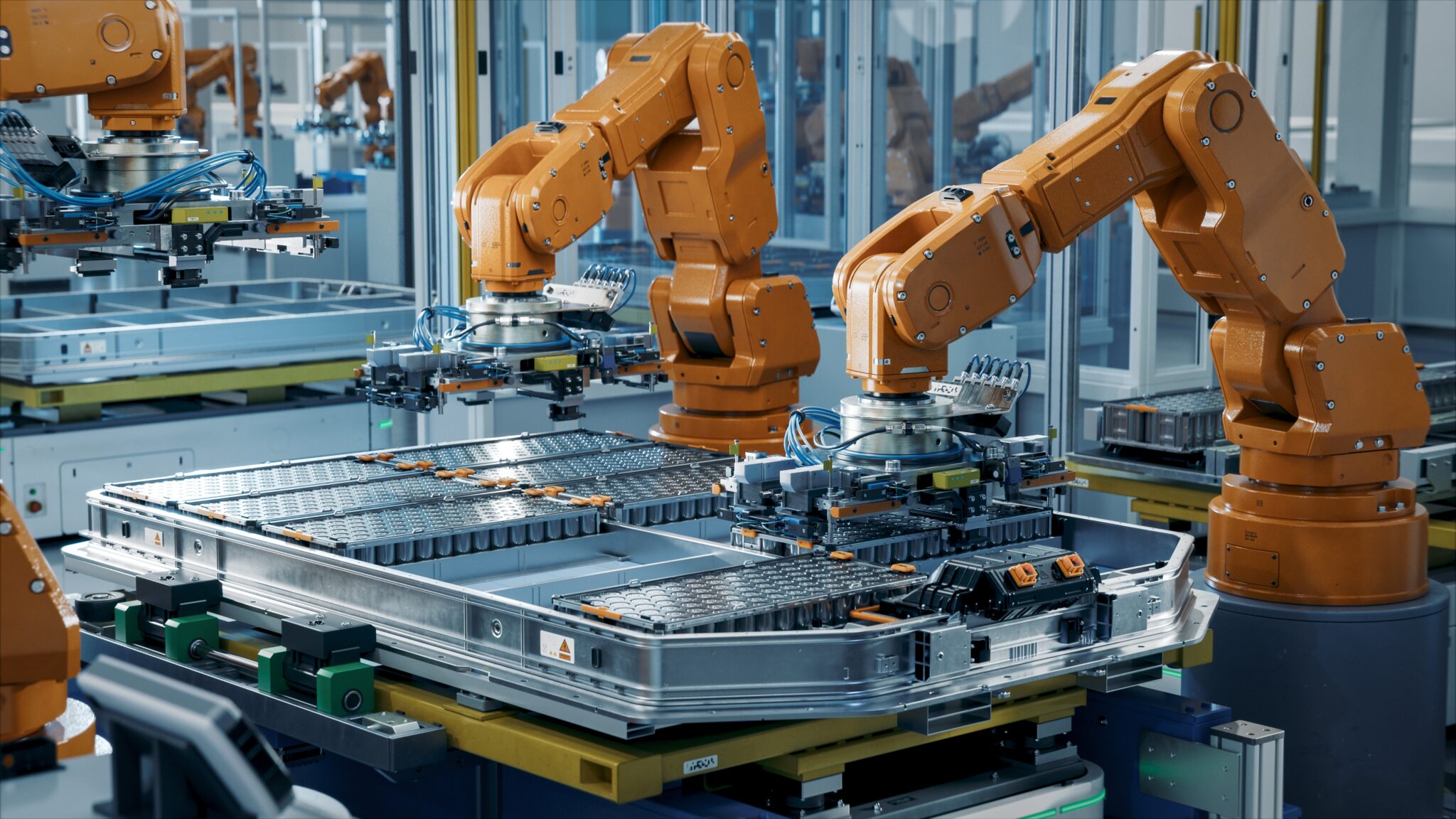

Industrial Automation

SINTRONES is driving industrial automation toward Industry 5.0, delivering reliable, intelligent, and human-centric Edge AI computing solutions. With our SBOX, ABOX, and SPC Panel PC product families, manufacturers can achieve:

-

Real-time visibility: Monitor production processes with Edge AI and machine vision to make faster, smarter decisions.

-

Predictive maintenance and quality control: Reduce downtime, ensure product consistency, and enhance operational efficiency.

-

Secure and resilient industrial computing: Built to IEC 62443-4-1 standards, ensuring cybersecurity is integrated from design to deployment.

From compact embedded systems to high-performance edge AI platforms and rugged industrial panel PCs, SINTRONES solutions empower smart factories, connected infrastructure, and intelligent transportation — enabling efficient, sustainable, and data-driven automation.